Traceability and Compliance Process

Together with Ata Marie, we worked to develop a detailed implementation plan to implement our NDPE policies to create the necessary conditions to transform our supply chain to one that is fully traceable and compliant to our sourcing policies.

Our traceability process begins with screening our existing and potential suppliers. This initial screening involves mapping and data collection, which will allow us to identify our supplier’s gaps and allow us to focus on ways we can assist them to improve and determine the appropriate assistance we could provide them. We recognize that small farmers require more assistance than others and we prioritize them in our supplier programs.

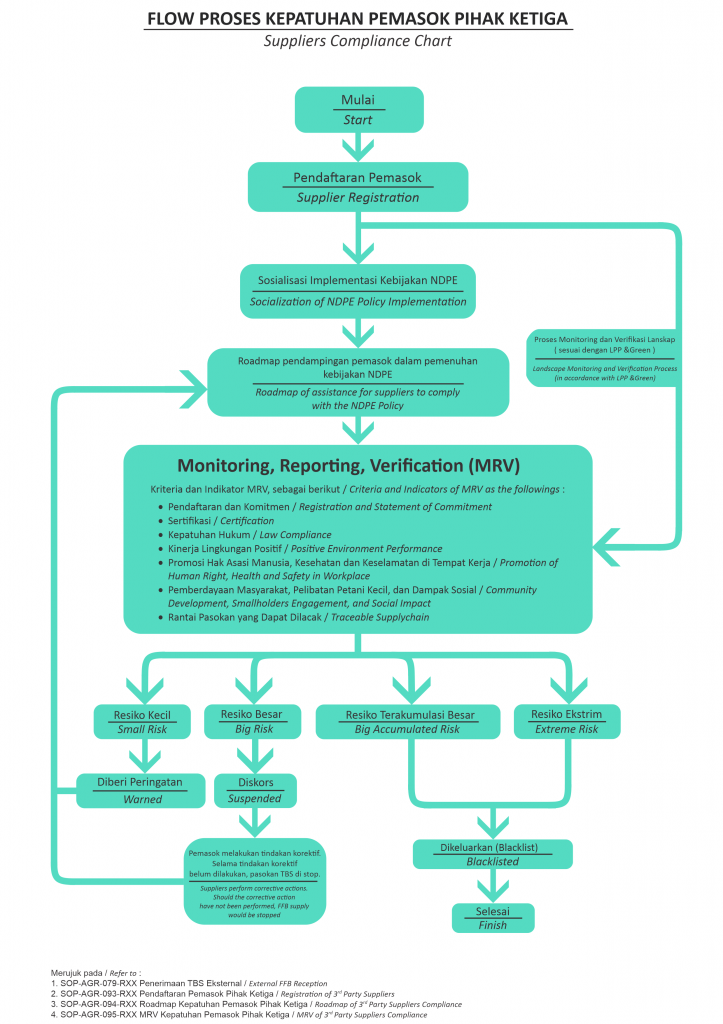

We describe the mechanisms for our traceability and compliance process in the following procedures:

A. MAPPING & TRACEABILITY of our FFB under SOP Third Party Supplier Registration

This process involves not just registering all our suppliers information and location, it also involves mapping key landscapes where our external suppliers operate and because of our Landscape Protection Plan commitment with &Green (LPP) we identify key areas which need protection.

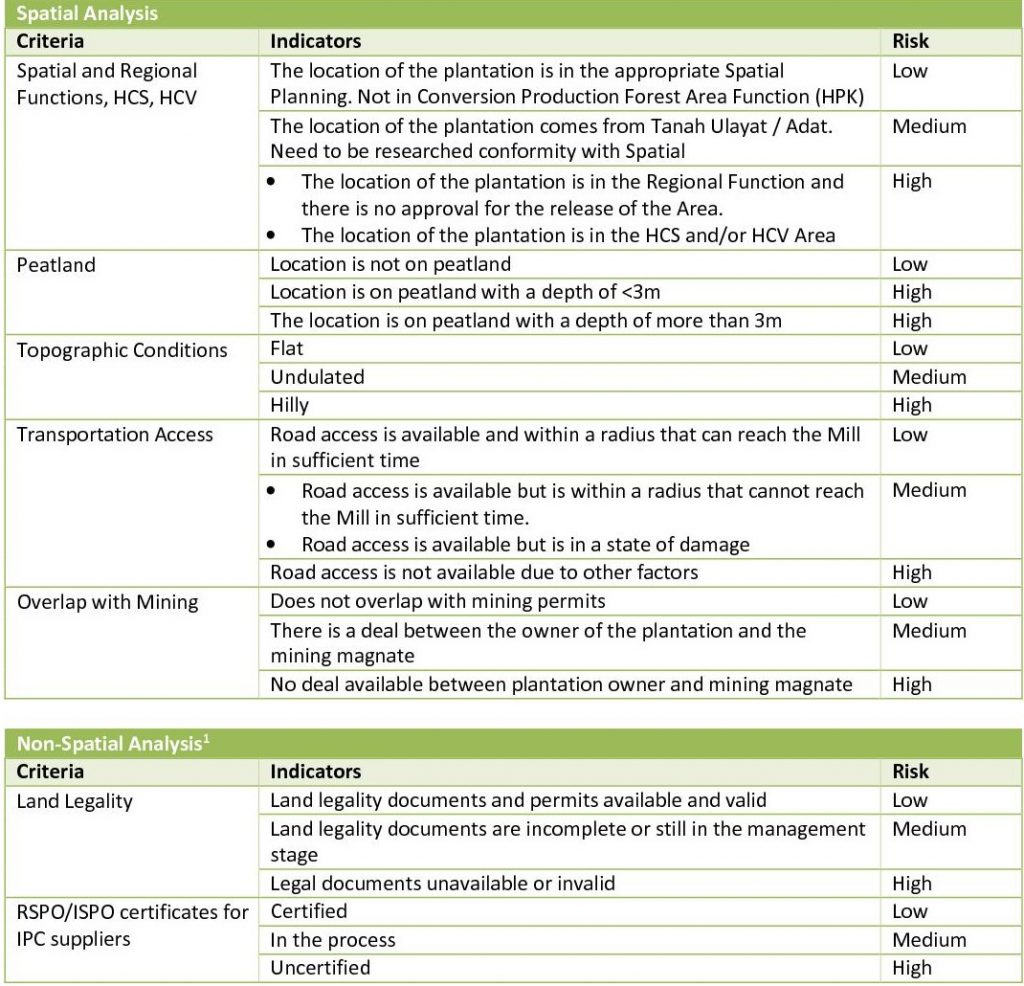

The key tools in this are spatial analysis and also site visits, to ground truth and verify the key areas that are the subject of our LPP. Methods of engagement used to register suppliers include site visits to individual suppliers, who are Independent Plantation Companies, Suppliers Cooperatives/Saprodi and Agents, as well as group meetings. In the supplier registration, we collect and assess data of our suppliers to determine their compliance level and risk levels.

The data we collect relate to the following information :

During such meetings we will also conduct awareness on our compliance requirements and share best practices with the farmers.

B. SOP External FFB Reception

At our mills we ensure all the FFB we receive are identified by source and we take additional efforts when it comes from external suppliers. This is important to ensure traceability of FFB and determine the source of FFB from third-party suppliers complies with our NDPE policy. Our process involves the following method :

- Supplier Eligibility Verification

- FFB Transport Truck Registration

- Verification of FFB Identity

- Truck Load Inspection

- FFB Truck Load Weighing

- Grading Process

- FFB Truck Empty Weighing

- Final Inspection of FFB Trucks

- Re-conciliation of External FFB Reception Data

At our mills, our employees use a proprietary computer software system to record, authenticate and verify the process above. Any FFB supply not meeting the said above requirement will not be accepted at our mills.

C. SOP Third Party Supplier Compliance Roadmap

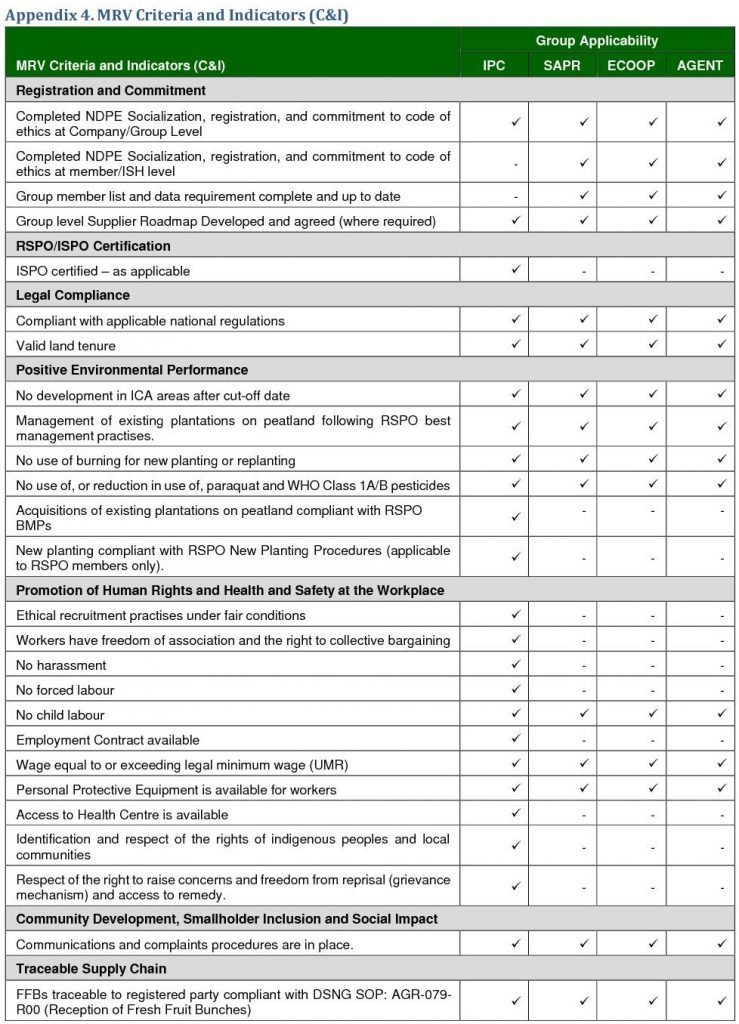

Our external suppliers compliance will be processed through a specific Program that will begin with socialization and training of our FFB suppliers with our NDPE policy. The process involves the signing of a Code of Conduct declaration, Self-Assessment training, compliance evaluation, polygon mapping, corrective action identification, corrective action scheduling, reporting of compliance test results, verification of corrective action results, and supplier compliance status declaration.

Each supplier, depending on their level of compliance will be monitored through a proprietary software tool. The said tool is a database application provided to manage the activities of third-party supplier compliance roadmap program containing features including storing MRV C&I (Monitoring, Verification and Reporting Criteria & Indicators), drafting socialization schedule, creating and storing socialization Minutes, due diligence, verification, monitoring and reporting related to the requirements of MRV C&I DSNG policy applied to third party suppliers.

Based on the each supplier’s compliance level, our team will track their progress in a timely manner as per designated compliance timelines given. While we recognize that our supply chain also needs the time and effort to comply, any supplier that does not provide a reasonable justification for not complying shall be suspended from supplying and will not be given any extension on the said timeline.

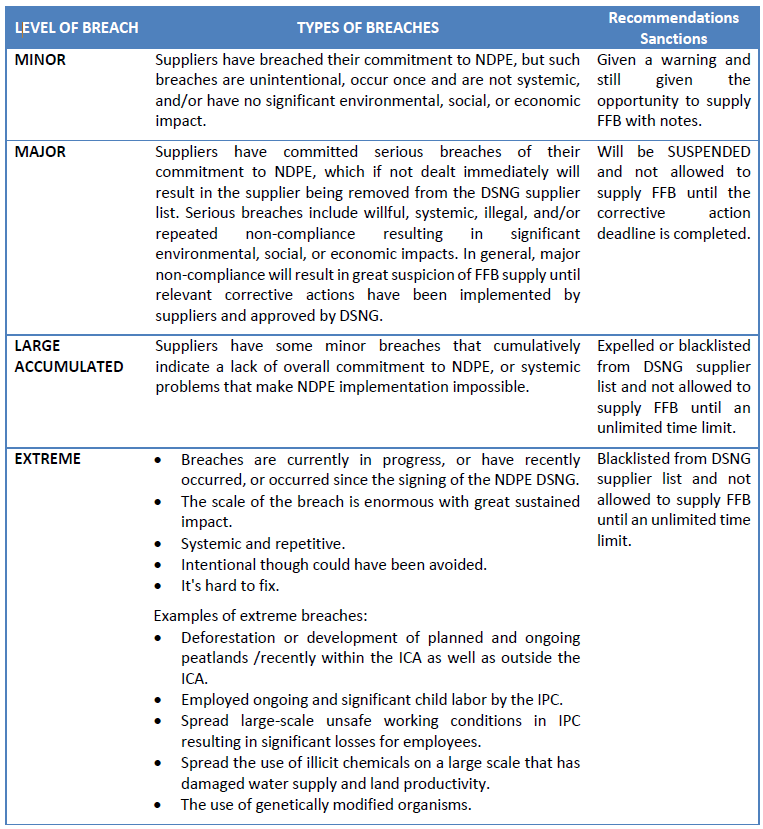

We regularly review the compliance levels of our external suppliers and we have specific criteria to determine if they should be suspended or excluded.

Below are the criteria and the relevant actions taken for non compliance to our NDPE or sourcing policies.

However we provide our suppliers with a reasonable amount of time to make the necessary improvements to comply with our policies. As provided in SOP-AGR-094-R00: Third Party Suppliers’ Compliance Roadmap, we allow the following time frame for suppliers to make improvements to comply:

a) IPC suppliers: 3 – 6 months

b) SAPR/ECOOP: 6 – 12 months

c) AGENT: 6 – 18 months

Any supplier that does not provide a reasonable justification for not complying shall be suspended from supplying and will not be given any extension on the said timeline.

Amongst others, the database application will track the following indicators for compliance :

Remarks:

IPC : A non-DSNG company-owned plantation that supplies FFB to a DSNG Mill.

SAPR (Sarana Produksi Pertanian/SAPRODI) : SAPR is a smallholder scheme. A partnership agreement is made between a DSNG plantation company and a community cooperative wherein DSNG provide a Limited Agricultural Production Facility Loan in various forms. DSNG buys all FFB produced from the cooperative for 1 planting cycle. The SAPRODI loan is deducted from FFB sales payments in instalments until the loan is paid off.

ECOOP (External Cooperative) : An independent smallholder cooperative that supplies FFB to DSNG mills. “Independent” here refers to absence of any DSNG support. Agent: An independent trader purchasing FFB from smallholders and selling to DSNG mills.

D. SOP MRV for Third Party Supplier

Our suppliers are subject to our Monitoring, Review and Verification (MRV) process. This process involves MRV Audits of third-party suppliers that are already registered as compliant suppliers and committed to NDPE policies. Audits are carried out periodically by our team or at any time to monitor supplier compliance if there is an alert from our compliance process or perhaps from an external source received from our grievance process.

These procedures covers several methods : MRV Audit planning, MRV Audit implementation, corrective action identification, corrective action scheduling, reporting of MRV Audit results, identification of breach rates and penalty recommendations, penalty determination, verification of corrective action outcomes, and supplier compliance status declarations. Additionally, we also rely on information from our grievance process which is open to all our stakeholders.

Information from the MRV will be again fed to our database application provided to manage the activities of third-party supplier compliance roadmap. The application program contains features, which amongst others, including storing MRV C&I, drafting socialization schedule, creating and storing socialization minutes, due diligence, verification, monitoring and reporting related to the requirements of MRV C&I DSNG policy applied to third party suppliers.

These 4 SOPs are interconnected as illustrated in the following chart :

Our Progress in 2020

Aligned with our Roadmap for compliance, DSNG has conducted socialization on the company’s NDPE, sourcing policies and legality requirements to its external suppliers, who are made up of Agents, Independent Plantation Companies and Farmers cooperatives(SAPRODI &ECOOP). The company does not purchase any palm oil directly from smallholder farmers.

A. Up to the end of December 2020 :

17 out of a total of 107 external suppliers (16%) of them have signed the supplier compliance statement.

B. Up to end of June 2021 :

100 suppliers out of 6080 farmers of the supplier cooperative farmer members have completed the assessment form.

C. December 2022

Until 2022, DSNG has provided training and socialisation on NDPE policy and required compliance to external suppliers. This initiative has been implemented for 9 out of 10 Independent Plantation Companies (IPCs), 21 out of 25 cooperatives, and 32 out of 56 FFB supply agents. The external suppliers that have not received socialisation are mostly newly registered suppliers and will be included in this initiative until the end of 2023. DSNG will continue to socialise until it reaches 100% of suppliers by the end of 2023. In addition, in 2022, a self-assessment of DSNG’s NDPE policy compliance was conducted by suppliers. This assessment was participated by several stakeholders, namely Koperasi Sumber Rejeki and Koperasi Sawit Usaha Tani Sejahtera in Wahau, Agent CV Eka Jaya in Bengalon, CV Wejas Imanuel in Wahau, and PT Perkebunan Warga Rimba (IPC).

D. Up to the end of 2023,

By the end of 2023, the socialisation process is targeted to reach 3,811 farmers. The realisation of NDPE socialisation to farmers has reached 3,637 farmers or 95.43% of the 2023 target. In addition, out of 80 DSNG suppliers in 2023, 76 of them (95.0%) have received NDPE socialisation and expressed their willingness to implement NDPE for their supplying farmers.

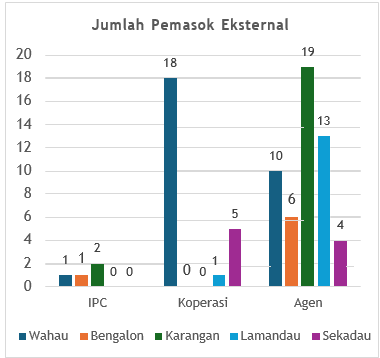

The number of external suppliers of each type in the DSNG landscape in 2023 is given in Figure 5. The number of suppliers is relatively fixed compared to 2022, except in Wahau with an additional 3 Agent suppliers, in Lamandau 1 Agent supplier, and in Sekadau 2 Cooperative-type suppliers. Of these suppliers, 100% of IPC and Co-operative type suppliers are registered. For Agents, 88% of suppliers are registered.

The Company reports that all its suppliers are subject to a Monitoring, Review and Verification (MRV) process involving third-party suppliers who have registered as compliant and committed to the NDPE policy. By 2023, the total number & percentage of suppliers out of 80 external suppliers, 74 suppliers are registered, resulting in 92.5% compliance or registered suppliers.

An engagement plan for smallholders has been formulated in a NDPE implementation roadmap for 2021-2025, which targets for our supply chain to be 100% traceable and compliant by 2025. Please our NDPE Implementation Roadmap here.