Biomass

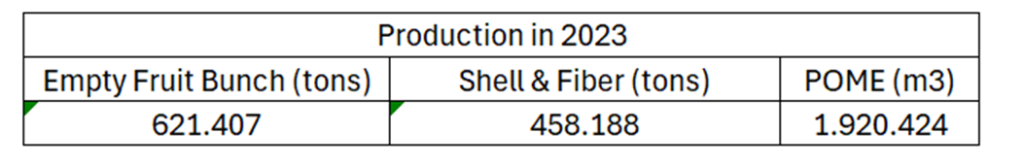

To reach the best practice for the zero waste palm oil industry, we continue to strive to maximize the reuse of all waste and by-products of the plantation and palm oil mills. The by-products include: pruning fronds, empty fruit bunches, fiber, shells, solids, and liquid waste of palm oil mills (POME), also household waste from the employee housing. A number of countries have started to switch to oil palm biomass because it is an environmentally friendly and renewable fuel source. Several studies showed that the biomass potential of oil palm empty fruit bunches is about 133.9 GW. These results show their great potential as a boiler fuel, although it must also be noted that the mineral/alkaline content is quite high. Biomass can also be converted into bio-coal as a substitute for coal. The use of biopellets or bio-coal to power plant fuel is more environmentally friendly because it can reduce greenhouse gas emissions. Of all the existing oil palm biomass, 70% are palm tree fronds, while empty fruit bunches reach 10%, and oil palm trunks reach 5%. A lot of oil palm trunk biomass will be produced during replanting. The biomass production by the palm oil mills of DSN Group in 2022 is as follows:

Current utilization of biomass in DSN Group:

Fronds

During pruning and harvesting, the leaf fronds are trimmed and placed in the soil to be processed into organic fertilizer, especially to increase the soil organic matter content. Fronds also help maintain soil moisture and reduce soil erosion.

Empty Fruit Bunches

One of the palm oil mill by-products with the largest volume is empty fruit bunches. The main use of empty fruit bunches is currently as an organic fertilizer and soil conditioner to improve soil structure.Some alternatives to the utilization of empty fruit bunches will continue to be developed to obtain optimal results.

Fiber & Shells

This is now a valuable renewable source of combustible energy and is increasingly sought after to replace non renewable or fossil fuel energy sources.

Solid

Solid production ranges from 3-5% of the total fresh fruit bunches processed, which are sent to the plantations and used for organic fertilization. The benefit of using solid is for the improvement of soil structure.

POME

POME is processed in wastewater treatment ponds to reduce acidity and BOD & COD levels so that it is safe to use as an organic soil fertilizer. Application permits (Land Applications) are obtained for each location, with strict monitoring of environmental impacts as required by laws and regulations (Decree of the Minister of Environment and Forestry Number 29 of 2003 concerning Guidelines for Requirements and Procedures for Permits to Use Palm Oil Industry Wastewater on Soils in Oil Palm Plantations). Besides being treated in conventional ponds, methane capture will be installed gradually in several palm oil mills to better capture all methane gas (CH4) from