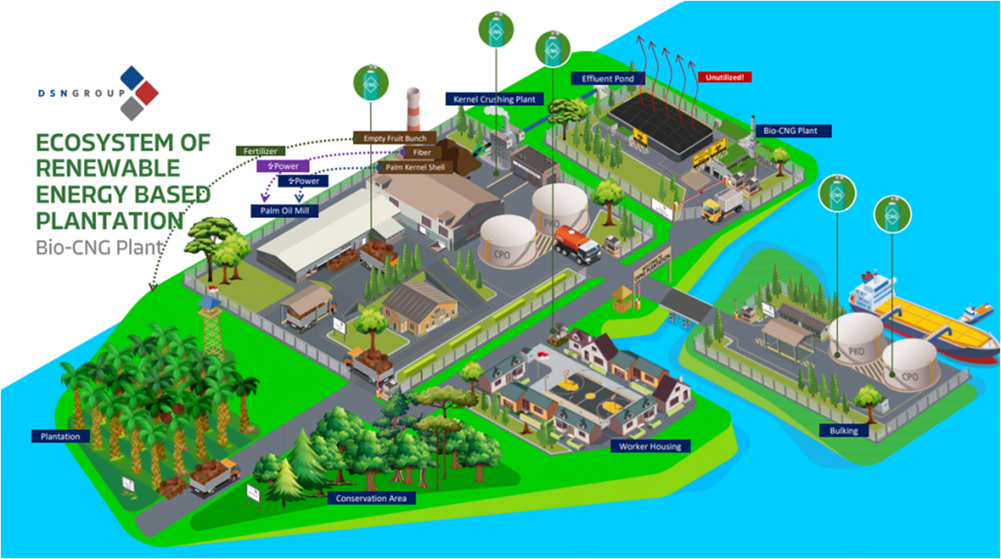

Biogas

In September 2020, DSN Group commissioned the first Methane Compressed Natural Gas Plant or Bio-CNG Plant in Indonesia for the palm oil industry. The electricity from the Gas generators is used to power our in-situ Palm Kernel Crushing Plant (KCP) which had previously depended on Diesel generators for power. The excess methane gas captured is further scrubbed or purified to approximately above 90% methane content and then compressed in the Bio-CNG Plant. The Bio-CNG gas is secured safely in gas containers for mobility to transport around our plantation. The containers of Bio-CNG gas are distributed to several sites in our plantations where it is used to replace fossil fuels typically in electricity generators, as well as in transportation vehicles.

Currently, DSNG has two Bio-CNG plants. The first one with a capacity of 2×600 kW and 280 Nm3/h, is operational in 2021. While Plant 2 is already operational in 2023 and in the process of being set up with a capacity of 2×850 kW and 540 Nm3/hour.

Bio-CNG Plant #1

Bio-CNG Output 1

This project provides DSN Group with a sustainable form of renewable energy (RE). Over the course of 2023, the Bio-CNG produced from Plant 1 has replaced 2.1 Million Litres of Diesel fuel for our power plants and vehicles. More importantly, it also reduces Greenhouse Gas emissions by approximately 50,000 tonnes of CO2 per year. In simple terms, this reduction of over 50,000 tonnes of CO2 is equivalent to planting over 800,000 trees or removing 11,000 units of passenger cars from use or eliminating 17,000 tonnes of landfill. Where the benefits are potentially manifold from the second plant. Indirectly, methane capture will also improve our wastewater treatment and thus improve water quality by reducing Biological Oxygen Demand (BOD).